There are many aluminum forging manufacturers in the industry today. But you need to be very careful when choosing because some of these manufacturers might not provide the kind of quality that you need. But there are so many good ones, but you might unlike to meet with the bad guys.

There are several things that make a good aluminum forging manufacturer. You need to understand these things when buying to get the right quality forgings. Read more below to understand the traits of a good manufacturer.

Vast Experience

The first aluminum forging manufacturer should have vast experience in forging. They should have been in the market a long time enough for them to fix all the major flaws in their system. This is an important factor. If possible, the manufacturer must have handled similar order as yours. Check the reviews.

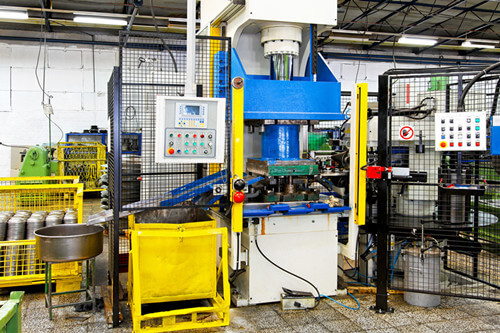

Quality machines and equipment

You cannot say an aluminum forging manufacturer is good if you have not checked the factory quality. There are a number of things you need to check in the factory, but the quality of the machinery and the equipment is crucial. An aluminum forging manufacturer that has not invested in the quality of the production line is not worth dealing with. This is an important factor to consider when choosing a manufacturer.

Forging Material Quality

Always check the grade of the aluminum forging manufacturer is using. Just because they are forging aluminum material does not mean they have the best quality material. Depending on the kind of forging you need, make sure that they have quality aluminum material. Otherwise, you might find yourself buying low-quality forgings.

Range of Products

There is an advantage that comes with buying from an aluminum forging manufacturer that can produce a range of products. This is important, especially if you are in a market that uses a range of products. A good example is the packaging industry, where you have a range of sizes and materials’ grade. The vaster the range of products, the better.

Communication

The aspect of communication is widely ignored when choosing an aluminum forging manufacturer, and that shouldn’t be the case. You need to deal with an entity that is responsive to your queries in a timely manner. This is an important factor to consider because you might be in need of crucial information that can save you from a lot of mess.