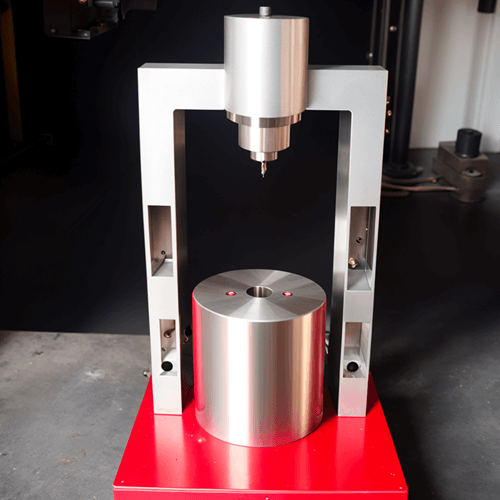

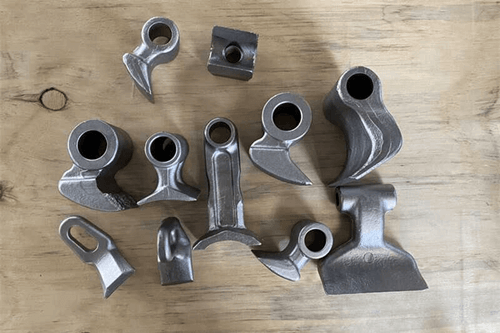

Hydraulic press machines are invaluable tools in metalworking industries, playing a crucial role in shaping, bending, and forming various metal components. These powerful machines rely on hydraulic systems to generate the force needed for these tasks. To ensure the longevity and efficiency of hydraulic press machines, proper maintenance is essential. In this article, we will discuss five must-have maintenance tips for hydraulic press metal.

Regular Inspection of Hydraulic Fluid

The hydraulic fluid is the lifeblood of a hydraulic press. It transmits force and lubricates the system’s components. Regularly inspecting the hydraulic fluid is crucial to maintaining the machine’s health. Check the fluid level and quality. If you notice any contamination, such as particles or discoloration, it’s time for a change.

Additionally, make sure to follow the manufacturer’s recommendations regarding the type of hydraulic fluid and change intervals. Proper fluid maintenance will prevent premature wear and tear on the press’s components and ensure optimal performance.

Lubrication of Moving Parts

Like any other mechanical system, hydraulic presses have numerous moving parts that require proper lubrication. Failing to lubricate these components can lead to increased friction, heat, and ultimately, component failure.

Create a lubrication schedule and adhere to it diligently. Focus on parts such as bearings, pistons, and guides. Use the appropriate lubricants recommended by the press’s manufacturer, as different components may require different types of lubrication.

Inspection of Hoses and Fittings

Hydraulic hoses and fittings are critical for the proper functioning of the press. Inspect them regularly for signs of wear, cracks, or leaks. Damaged hoses or fittings can lead to hydraulic fluid loss, reduced pressure, and potentially dangerous situations.

Cleanliness Is Key

Maintaining a clean workspace and machine is essential for hydraulic press maintenance. Metal shavings, dust, and debris can find their way into the press’s components, causing damage over time. Regularly clean the press, paying special attention to areas around moving parts and the hydraulic reservoir.

Training and Documentation

Proper maintenance of hydraulic press metal machines also involves well-trained operators and detailed documentation. Ensure that your operators are trained in the correct operation and maintenance procedures. Encourage them to report any issues or abnormalities promptly.

read more about the hydraulic press machine and their maintenance on that website.