If you are planning to buy automotive forging parts, there are a number of things that you need to consider. To help you make the right choice, we have put together a number of tips and tricks that can help you get the right parts as well as get value for money. Check out the following:

Size

Always remember to check the issue of size when buying automotive forging parts. There are so many sizes of automotive machines in the market, and thus the size of the parts will also vary. The most important thing is to ensure that you have checked the size of the automobile you are working on to get the right size. This is important.

Brand

The other crucial thing you need to consider is the brand you are buying. Like most of the products in the market, branding is very crucial in forged parts. For your automobile to use the best quality and standard parts, you need to ensure that the manufacturer has the capacity to produce the parts. The good news is that there are so many brands in the market that you can select from. Just make sure the brand has a good reputation in the market.

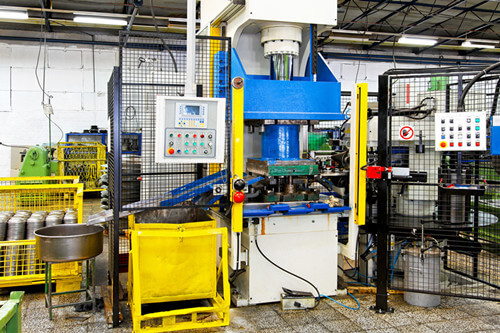

Materials and Production

The other way that you can identify quality automotive forging parts is the materials used for their construction. You also need to know the method used for their production. Depending on the condition the automobile will be used in, you need to ensure that the quality of the material used meets the standards. So by just checking the material the manufacturer uses, you can tell the quality.

Cost

The cost of the automotive forging parts is another important factor that you need to consider. Make sure that you are getting value for money. This must always be the most important thing to consider when it comes to buying any machine parts. Make sure that you are getting the best quality forging but at the most affordable price. This is important to consider.

Longevity

Another important thing that you need to consider is the longevity of the automotive forging parts. How durable are the parts, and can they meet your expectations? These are very important factors to consider if you are looking for parts you would want to serve you for a long time. These are some of the crucial factors that you need to consider