Are you going to the market for the first time? You need to get the right aluminum forging suppliers. Otherwise, you might end up buying from fraudsters selling fake and counterfeit products. But what should be guiding you when selecting a supplier?

Well, there are several things that you need to check when making a selection. That’s what we have for you in this guide. But if you want to go direct to one of the best aluminum forging suppliers, click here. They have a range of forgings for you.

Here are buyers rules when selecting aluminum forging suppliers:

Always Check Experience

Start with checking the experience that the aluminum forging supplier has in the market. To be more price, you need to check the experience they have in producing the products you need. The longer the experience, the better the aluminum forging supplier is.

Do Not Compromise Quality

Do not ever compromise on the quality of the forgings that you need. You must always know the quality of the products that you need and then look for a manufacturer that delivers. Make sure that you have stuck to that quality no matter the incentives offered.

Location matters

The location of the aluminum forging suppliers matters a lot. You don’t want to buy from a manufacturer that is located thousands of miles away if you need the product as soon as possible. So make sure that you are working with an aluminum forging supplier near you if possible.

Get the Best Prices

Always ensure that you are getting value for money no matter what. But this does not mean compromising the quality of the forgings. So make sure that you are selecting a manufacturer that offers the best prices.

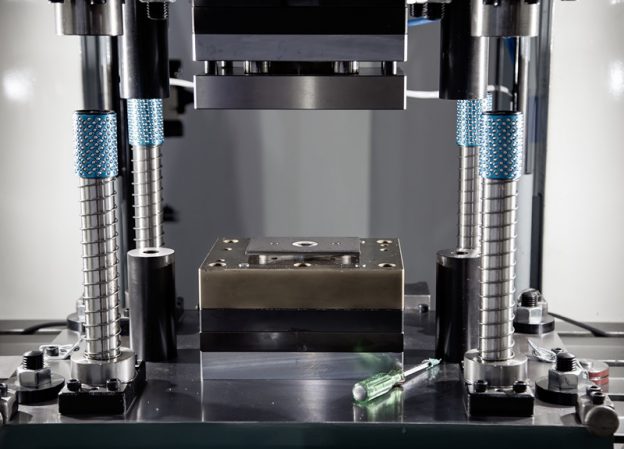

Factory Quality Matters

The quality of the factory is also an important factor when selecting aluminum forging suppliers. Make sure that you are buying from a manufacturer with a production line that can offer the best quality forgings. That’s one way to ensure quality.

Production Rate Is Crucial

The rate at which the manufacturer is producing forgings is a crucial factor. You need a manufacturer that works and delivers the order within a very short time. That’s why you need to consider the issue of production rate seriously.

Efficient Communications

Last but not least is the efficiency of communication. Only deal with aluminum forging suppliers that have efficient communication. This is an important factor to consider when selecting a supplier.