If you are looking for flexographic printing plate suppliers, we have some interesting things for you in this blog. These are things that you need to consider when it comes to selecting the best supplier. First, it is important to mention that there are so many of them in the market in the market. So, you need to be very choosey to ensure that you have gotten the most reliable one.

You can click here to see one of the best flexographic printing plates supplier in the market today. They have a range of engraving machines for making flexographic printing plates.

Here are tips that will help you select the best flexographic printing plate suppliers:

Production Experience

The first and most crucial tip that you need to consider is how established the supplier is. How long have they been in the market? Have they been in the manufacturing industry for long? These are very pertinent questions to consider when selecting flexographic printing plate suppliers. The longer they have been around, the better they can offer quality services.

Market Reputation

The next important tip for choosing flexographic printing plate suppliers is checking their reputation in the market. That’s why it is important to start with checking the experience because the more years they have been in the market, the easier it is to check their reputation. This is because there must be many people who have bought from them. Go for a good reputation.

Technology Advancement

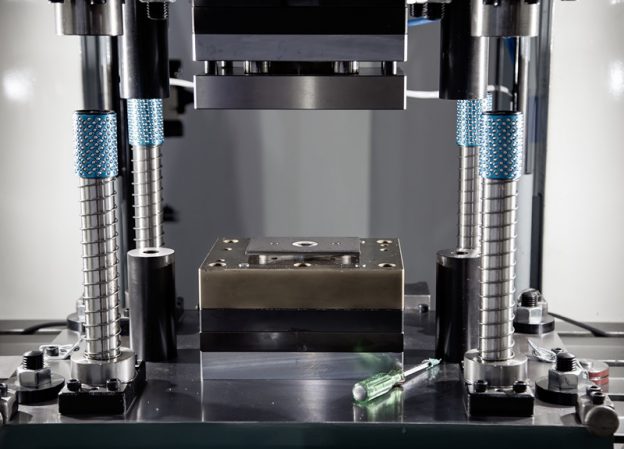

Every flexographic printing plates supplier has a distinct application of the technology. Some have been able to customize engraving technology to produce more reliable machines. That’s why you need to first have an idea of the technology that you need to enable you to do a proper selection. The more advanced the technology, the better.

Availability/Location

The best flexographic printing plates supplier is the one that is available or near you and offers the quality you need. Working with a closer manufacturer ensures that you have better access to the machine and replacement parts when you need them. This will help reduce the issue of downtimes in your operations.

Cost of Machine

The other important tip in choosing flexographic printing plate suppliers is the cost of the machine. This is an important factor to consider because it will greatly determine how much you spend on the machine. Go for the cheapest supplier without compromising quality.